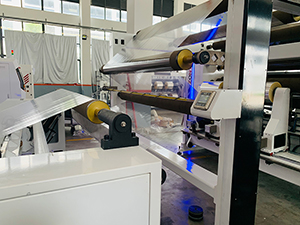

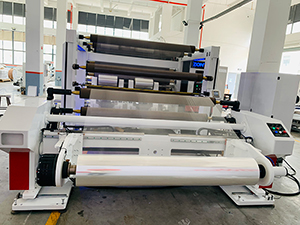

Shelf Type Film Slitting Machine, ZTM-G 2000

Shelf Type Film Slitting Machine, ZTM-G 2000

The ZTM-G 2000 shelf type film slitting machine is mainly applied to slit cellophane, PET, OPP, CPP, PS, PVC, optical materials, film roll, etc.