Zontai, with nearly 20 years of experience in the converting industry, can offer a broad range of slitting rewinding machines to accommodate all the global market requests. Our slitter rewinders are available for plastic films, paper, metal foils, fabric and other materials.

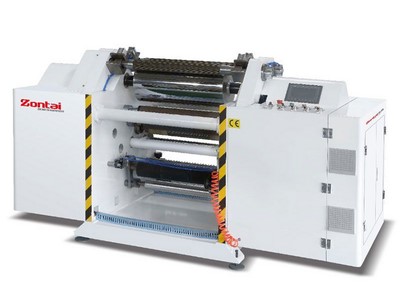

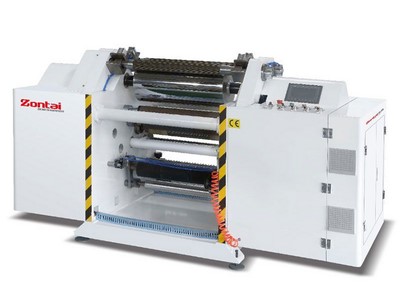

Max. slitting speed of 800m/min;

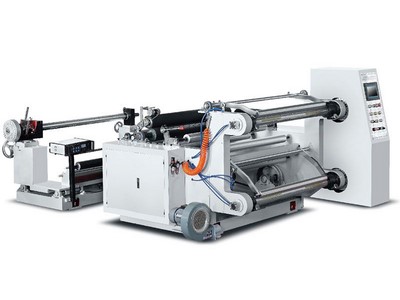

It is suitable for converting a wide range of plastic films, and can automatically perform unwind width adjustment, mother roll loading and unwinding.

This integrated slitting machine is specifically designed to meet the needs of businesses prioritizing high output and time efficiency. It is ideal for processors seeking fully automated solutions while ensuring minimal roll tension and scratch-free roll surfaces.

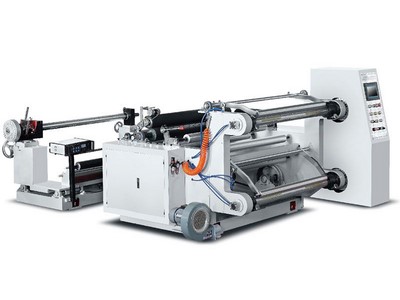

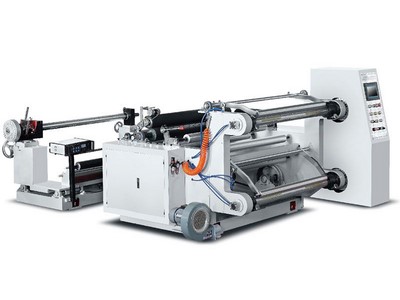

Max. slitting speed of 600m/min;

It is designed typically to handle a variety of films including optical film, PET release film, BOPP film, PVC film, PET film and PE film at high speeds. It allows user to easily rewind various materials due to two servo motors at the rewind station.

Max. slitting speed of 600m/min;

The ZTM-G 2000 shelf type film slitting machine is mainly applied to slit cellophane, PET, OPP, CPP, PS, PVC, optical materials, film roll, etc.

Max. slitting speed of 400m/min;

It is an economical solution for converting a single parent roll into several smaller rolls, capable of slitting and rewinding of various materials such as PET, OPP, CPP, PE, PS, PVC, cellophane, anti-counterfeit labels, optical film, foil, laminates, paper and printed substrates.

Max. slitting speed of 400m/min;

It is built with structure of unwind and rewind at the same side, and ideal for converting PET, OPP, CPP, PE, PS, PVC, cellophane, anti-counterfeit labels, optical films, foils, laminates, kraft paper, adhesive paper, fabric, coated paper and printed substrates.

Max. slitting speed of 500m/min;

It adopts three servo motors, and is suitable for processing rolls of both paper and film such as cellophane, PET, OPP, CPP, PS, PVC, PE, optical film, as well as unprinted and printed paper with a thickness range of 10-500 microns.

Max. slitting speed of 400m/min;

It is versatile for slitting any kind of paper and film rolls including PET, OPP, CPP, PE, PS, PVC, optical film, and release film with a thickness range of 12-200 microns.

Max. slitting speed of 160m/min;

It is an economical choice for slitting various roll materials of PVC, PET, BOPP and PE films, with two rewind shafts.

Max. slitting speed of 300m/min;

It is especially used for rewinding film rolls or paper rolls. It has a web guide system to solve all issues of web alignment.

Max. slitting speed of 200m/min;

It is ideal for processing various materials with small size, such as PVC, PET, BOPP, laminates and paper rolls.

Max. slitting speed of 180m/min;

It is suitable for slitting and rewinding a mother roll of various materials including BOPP, PET, CPP, PVC, aluminum foil and kraft paper into several narrower widths.

Max. slitting speed of 600m/min;

It is an ideal solution for converting a variety of materials such as kraft paper, newspaper, silicone coated paper, thermal paper, fluting paper, sublimation paper, glassine paper, double side coated paper and recycled paper, with a web width range of 1600-3000mm.

Max. slitting speed of 350m/min;

It is primarily used to slit large rolls of adhesive sticker paper, kraft paper with width range of 1600mm-2700mm. Two rewind units are located adjacent to each other for great convenience of finished roll unloading.

Max. slitting speed of 350m/min;

It is primarily used to convert a master or parent roll of paper, kraft paper or self-adhesive paper into several smaller rolls, with a web width of up to 2100mm.

Max. slitting speed of 250m/min;

It is suited to cut down the parent roll of paper materials such as paper, kraft paper and adhesive labels into desired widths, and then rewind the final product back into narrower rolls with one rewind shaft.

Max. slitting speed of 400m/min;

It is built with structure of unwind and rewind at the same side, and ideal for converting PET, OPP, CPP, PE, PS, PVC, cellophane, anti-counterfeit labels, optical films, foils, laminates, kraft paper, copy paper, adhesive paper, fabric, coated paper and printed substrates.

Max. slitting speed of 180m/min;

It is suitable for slitting and rewinding a mother roll of various materials including kraft paper, BOPP, PET, CPP, PVC, and aluminum foil into several narrower widths.

Max. slitting speed of 200m/min;

It is ideal for processing various materials with small size, such as PVC, PET, BOPP, laminates and paper rolls.

Max. slitting speed of 150m/min;

It is mainly designed for slitting thermal paper rolls, bond paper rolls, cash register rolls, fax paper rolls, POS paper rolls, ATM paper rolls, and other small ribbon rolls.

Max. slitting speed of 400m/min;

It is versatile for slitting pure aluminum foils of 6 to 20 microns in thickness, as well as any kind of paper and film rolls including PET, OPP, CPP, PE, PS, PVC, optical film, and release film with a thickness range of 12-200 microns.

Max. slitting speed of 180m/min;

It is suitable for slitting and rewinding a mother roll of various materials including aluminum foil, kraft paper, BOPP, PET, CPP, and PVC into several narrower widths.